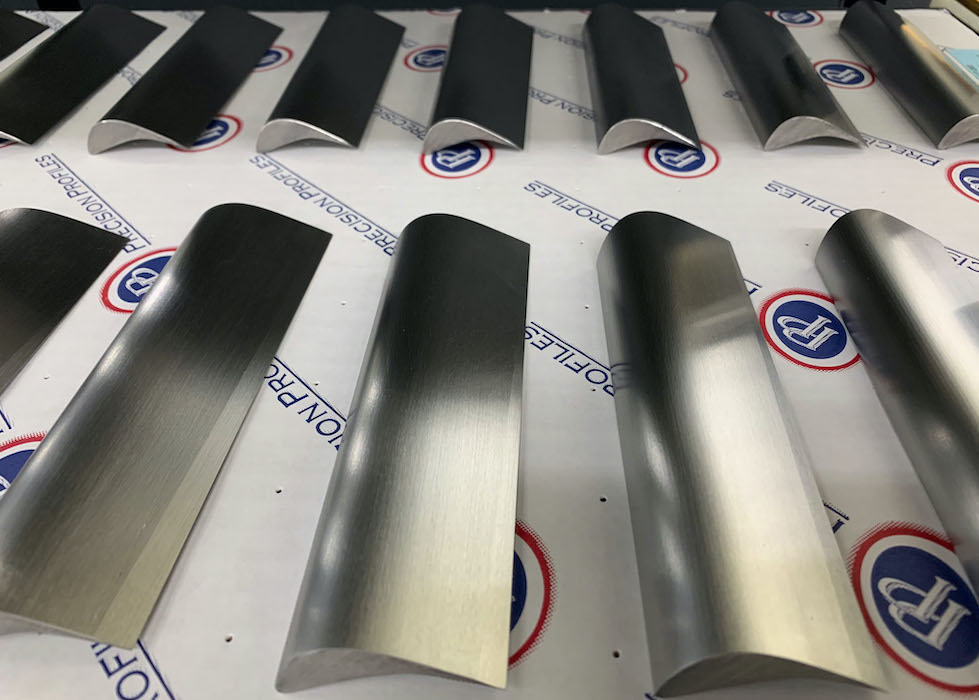

Specializing in Turbine Vanes

Precision Profiles has been manufacturing OEM steam turbine components for over 25 years. We specialize in steam turbine vanes (diaphragm nozzles, nozzle blades) for manufacturers such as Siemens, Dresser Rand, Westinghouse, Elliott, Delaval, General Electric, Conmec, Hickham, Worthington, and Murray to name a few. Our goal is to provide you with OEM-quality steam turbine components at a lower cost and with less lead time than your internal operations and our competitors’. Contact us today to learn more.

Contact us today for a free quote and analysis of your steam turbine component needs.

In addition to steam turbine vanes, we manufacture other components such as:

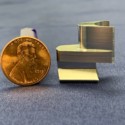

- Bucket blades / rotating blades

- Locking tabs

- Shroud material

- Band material

- Forged rings

- Spacers

- Inner Bands

- Outer Bands

Whether you are building a new turbine or overhauling an existing unit, our team of experts can help you:

-

Reduce component costs,

-

Increase overall production capacity, and

-

Improve turnaround times.

Value-Added Service

Our proprietary process for manufacturing steam turbine vanes (diaphragm nozzles) allows us to produce higher quantities, at a lower cost, and with faster lead times than our competitors – and those MRO shops manufacturing the parts in-house. By partnering with Precision Profiles, you can eliminate the time necessary to machine turbine vanes or other components for your current project – and can re-allocate this time and these resources to final assembly. Depending on what works best for your production process, we offer OEM turbine vanes in two configurations:

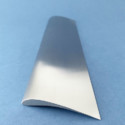

Finished Profile Bars

Finished Parts

Finished Profile Bars

-

36” -72” in length

-

Surface finish of 63 RA or better

-

Ready to cut finished vanes from bars

Key Tolerances:

-

Profile +/- 0.002”

-

Chord length +/- 0.004”

-

Trailing Edge Thickness +/- 0.002”

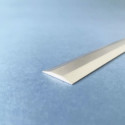

Finished Parts

- Cut to final length per drawing or customer specifications

- Cut options:

• Saw Cut (End Cut Surface Finish of 125-250 Ra)

• Wire EDM (End Cut Surface Finish of 30-60 Ra)

- Ready for installation

Key Tolerances:

- Profile +/- 0.002”

- Chord length +/- 0.004”

- Trailing Edge Thickness +/- 0.002”

- Length: Saw Cut +/- 0.005” Wire EDM +/- 0.001”

Fast Response Times

To ensure we can meet the needs of our customers, we regularly stock various shapes and sizes of stainless steel in grades of 403, 403cb+, 405, 410, 415, and 422. We offer both expedited and standard turnaround times depending on your project requirements.

Contact us today for a free quote and analysis of your steam turbine component needs.

Get Answers and Advice

Our goal is to answer all your questions in a timely manner.